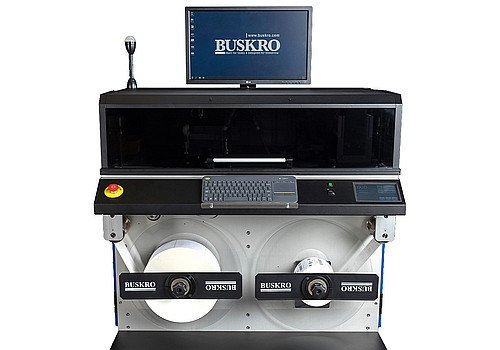

Intended for late-stage personalization of labels, BUSKRO Digital Label Press (DLP) is a high-volume inkjet printing solution that outputs a high-resolution print image when you want to add variable data images to your labels while minimizing both waste and production time. Designed to accommodate labels up to 5” (127mm) wide, either in a single or multi-lane layout, with a maximum roll diameter of 19” (482mm) on a standard 3” (76mm) core, the DLP can produce variable images at speeds up to 190 fpm (60 m/min) on a wide variety of materials including most common paper label stocks, both plastic and metal film, and textiles. Twin servo-driven spools, constant tension control and a smooth motion profile ensures optimal print conditions and precise label stopping and positioning; characteristics vital for the successful operation of the system. The thread path is kept compact and simple, conceived to quickly load the label spool with minimal front-end and back-end roll waste.

BUSKRO High-Speed Inkjet Label Printing System

Only 9804,

Per today 23

Canada

Buskro Ltd

Canada

Buskro Ltd

Founded in 1976, Buskro has evolved into an industry leader in the design and manufacture of high quality printing, tabbing/labelling and card processing equipment to meet a broad range of customer needs. Innovation is the key to everything we produce. Our approach of using the latest technology, along with an open architecture, allows our products to meet your current needs and adapt to your future requirements. Buskro equipment features heavy-duty construction from top to bottom, plus design details that promote years of trouble-free operation. Our commitment to innovation has produced solutions that have not only set the standard, but raised the bar for over 40 years. Working with Buskro’s global network of distribution partners, we take pride in providing quality service and support for all of our products, including our legacy technologies. When you consider your needs – the ones you face today and the unknown challenges of tomorrow, and then compare Buskro’s total value proposition of price, flexibility, quality and durability

Characteristics

-

Capacity/min. pcs/min1200

-

Coding typeink

Description

More from the manufacturer