Vials, bottles, cans, buckets and conical shaped cups have already become common and familiar to us in packaging of various products. In retail outlets, you can find a wide selection of products manufactured in such containers: yogurts, sauces, condensed milk, alcoholic and non-alcoholic drinks, sports nutrition, cosmetic creams and others. In highly competitive environment manufacturers develop new, even more original and more convenient for the consumer containers on the basis of the main cone format (for example, an hourglass PET bottle, which is widely used for filling mineral water and sweet carbonated drinks).

Labeling cone containers is technically more difficult than applying labels on cylindrical or square containers. This is due to its instability caused by the difference in diameters at the base and closer to the neck. Thus, the risk of falling and damaging the container, as well as unevenness of the label sticking, increases. To avoid this, modern labeling machines are equipped with additional elements that ensure the immobility of the vials. If there is none, then the load on the staff increases due to the need for constant monitoring containers positioning.

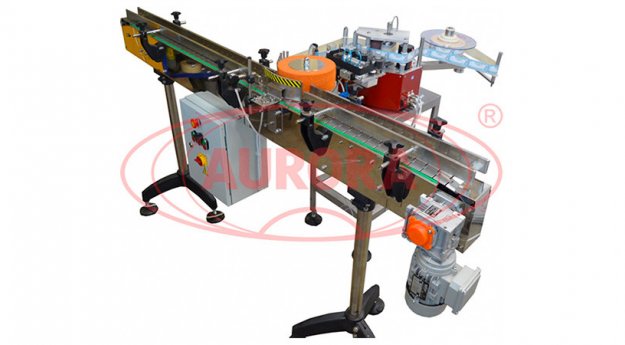

For fully automated complexes for packaging products in conical containers experts of “AURORA PACK ENGINEERING” have developed labeling line AE-5 with a capacity of 5000 vials per hour. The unit is easily integrated with capping group, banding group and exit tables using a linear or slat-type conveyor (in accordance with the modification).

Sticking labels is implemented directly by the universal applicator AURO-500C. Its work is synchronized with the roller, which smooths the label immediately after application, distributing it tightly on the surface of the container. An additional pressure plate is installed to fix light, shallow and other unstable containers. The machine is equipped with a dater for date, lot number and other data. When each new label appears, an optical sensor is triggered, which eliminates the device’s operation if there is no container or label on the package.

To ensure maximum accuracy, the model is equipped with a stand for the applicator with the ability to adjust its position in three planes (X/Y/Z). Thanks to such equipment, the manufacturer can decorate their products with labels of any, even non-standard shape, and place them on the package at different angles relative to the vertical axis.

One of the key advantages of this labeler is the ability to quickly changeover to a different container and label size. Changing the roller and reconfiguring other elements takes no more than 15 minutes. The versatility of the equipment included in the line allows you to successfully use it for labeling cylindrical containers. This makes the machine especially popular by enterprises that practice frequent packaging format changes or produce several product lines.

The basis of the machine control is a highly intelligent PLC-based module. The system is synchronized with a common tuner, and adjustments are made from a single touch panel. Conveyor speed, label feed, pre-departure — any process can be configured in accordance with the selected technology with one touch of the screen. The final performance of the machine depends on dimensions of the container, the format of the label, the specified interval between the containers and other parameters.

If you are in search of effective equipment for labeling cone containers, please contact “AURORA PACK ENGINEERING”. We adapt AE-5 line to any peculiarities of your production, we will set up and launch it. A wide selection of proposed modifications will let you find the best budget and functional solution for everyone!